In the earlier days of multibeam surveys, there was never a requirement for water column data. In fact, the earlier shallow water MBES did not output formatted water column data. However, when the data were processed, many multibeam surveys failed to pick up high points of obstructions, such as a sunken vessel’s mast. The lack of detection drove the initial demand for water column data over possible obstructions. Were these high points really not detected, or had they been processed out?

From the 1990s through the early 2000s, the most successful shallow water multibeam echosounders were produced by one company. That company developed a testing procedure to assign certain ‘quality flags’ to each sounding that was output.

Each sounding was tested for:

- Brightness which refers to the strength of the signal or sounding, a strong return

- Collinearity which refers to how well the sounding agrees with neighboring soundings

There were four ‘quality’ states.

- Quality 0 – poor collinearity, poor brightness

- Quality 1 – poor collinearity, good brightness

- Quality 2 – good collinearity, poor brightness

- Quality 3 – good collinearity, good brightness

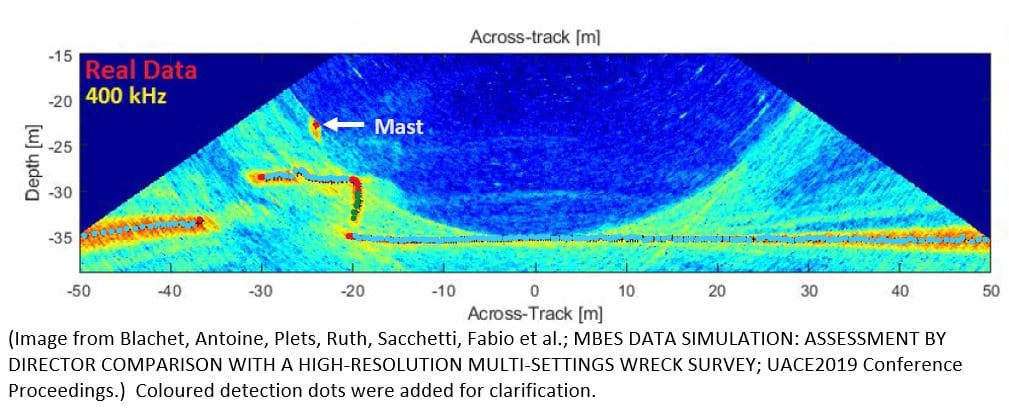

In the multibeam sonar display, the dots could be colored by quality.

- Quality 0 – Grey

- Quality 1 – Red

- Quality 2 – Green

- Quality 3 – Cyan

The surveyor had the option to display all the dots or only those that were Quality 3. The sonar did not delete any soundings based on the Quality factor; all soundings were exported with the Quality indicator. It was thought the Quality flags would be an aid to surveyors and data processors; they did not realize that those same surveyors and data processors would use the Quality flags as a shortcut in processing the multibeam data.

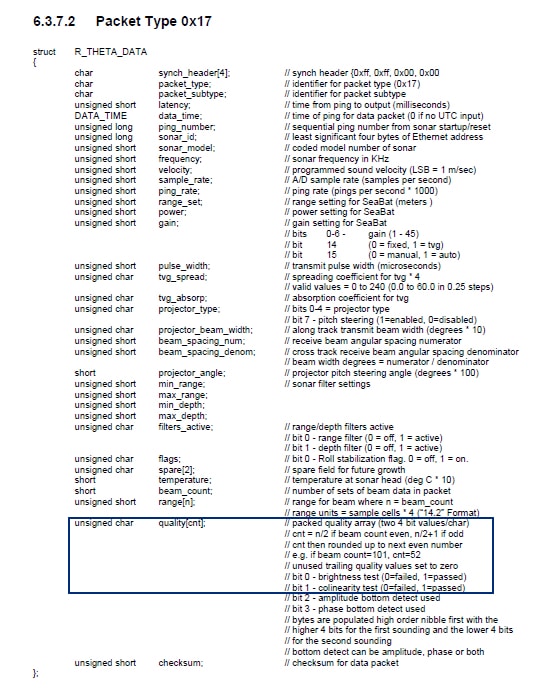

The multibeam sonar’s output format contained the quality information for each sounding.

When processing data from these sonars, all processing software can filter the data based on the Quality indicator, which is where issues arose; only Quality data was accepted.

Robust bottom tracking algorithms have to be optimized for likely seabed geometry. To avoid excessive outlier density, mistracking on spurious echoes is often discouraged by the use of gating or neighbor-proximity rules. Such methods, however, can fail spectacularly on abrupt non-continuous surfaces, commonly found over submerged man-made structures like wrecks or oil and gas infrastructure. These structures are often unsuspected and imaged only in a random pass of a regular survey. Based on prior experience, the least depth determination is often questionable from the real-time bottom tracking solutions. The main submerged superstructure is usually apparent but concern over protruding features can result in the need for bar or wire sweep investigations. (Clarke, John Hughes, Lamplugh, Mike, Czotter, Kalman; Multibeam Water Column Imaging: Improved Wreck Lest-Depth Determination, Canadian Hydrographic Conference 2006)

Many data processors would determine that only Quality 3 data points should be used. Without looking through the data before running filters, the option to filter out Quality 0, 1, and 2 data was selected, or only to accept Quality 3 data.

Quality 3 – Good Brightness, Good Colinearity •

Quality 2 – Poor Brightness, Good Colinearity •

Quality 1 – Good Brightness, Poor Colinearity •

The mast, which sticks up from the wreck, is a Quality 1 detection; the data processor would filter it out. The result of the processing would be an ‘undetected’ high point and a danger to navigation.