The transmit and receive elements are covered by polyurethane. Direct sun can dry out polyurethane and cause it to crack and become brittle.

If the sonar is mounted on an over the side pole, it is important to provide a cover for the sonar head when it is up and in its stowed position.

There has been a small number of systems that required extensive repairs due the exposure to the sun and the drying out of the polyurethane. Light colored canvas works very well.

When the head is recovered, it should be rinsed down with fresh water; this includes the sound velocity probe. It is recommended that during the washing process inspect the sonar head for any signs of damage.

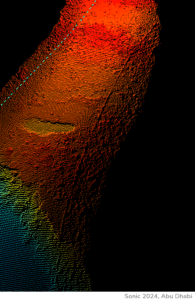

Some installations are such that the head is immersed in water long enough to have marine growth on the head. First, if you are installing a hull mount, moon pool mount or any mounting arrangement where the head will be immersed for long periods of time, please consider the R2Sonic antifouling coating. Contact your local R2Sonic representative for further details.

Head Cleaning

When the head has marine growth, it has to be removed. Marine growth, on the sonar head, will reduce the transmitted radiating power (when covering the projector) and reduce the receive sensitivity (when covering the receive elements). Marine growth can also attack the polyurethane causing physical damage.

First, try to remove as much growth as possible with a non-metallic, non-abrasive pad like might be used for washing dishes. A flat, wooden scraper, like a rice paddle works also. The key is to take it slow and not to try to get all growth off with the first attempt.

Second, you can also use certain acidic liquids, such as Barnacle Buster. It is 85% phosphoric acid and it must be diluted down to 20%. Contact time has to be limited to less than 5 minutes.

There may be household cleaning agents that will work. Some shower and bath cleaners are designed to remove lime deposits (as an example Limeaway™) and they will work. Mostly they have a very weak solution of phosphoric acid.

The main thing is for the customer to take it very slow and to not use any mechanical means (such as a grinder) and, in fact, use nothing but hand power and non-metallic pads or scrapers. After the hand cleaning, then follow up with a much diluted solution of phosphoric acid.